How SR&ED Tax Credits Can Benefit Your Custom Fan Manufacturing

Custom fan manufacturing for industrial applications involves tackling unique technological challenges that can qualify for Scientific Research & Experimental Development (SR&ED) tax credits. This valuable program supports Canadian businesses engaged in R&D by reimbursing a portion of the costs associated with experimental development. If you’re in the business of producing centrifugal and axial fans, here’s how you might be eligible for SR&ED incentives:

Material Selection for Fan Blades

Technological Uncertainty: Selecting the optimal materials for fan blades is a complex task. Factors like strength, weight, and corrosion resistance must be carefully considered. The best material may not be obvious and requires extensive testing.

SR&ED Activity: Conduct experiments to evaluate different materials for performance under various conditions. Your goal is to enhance the efficiency and durability of fan blades.

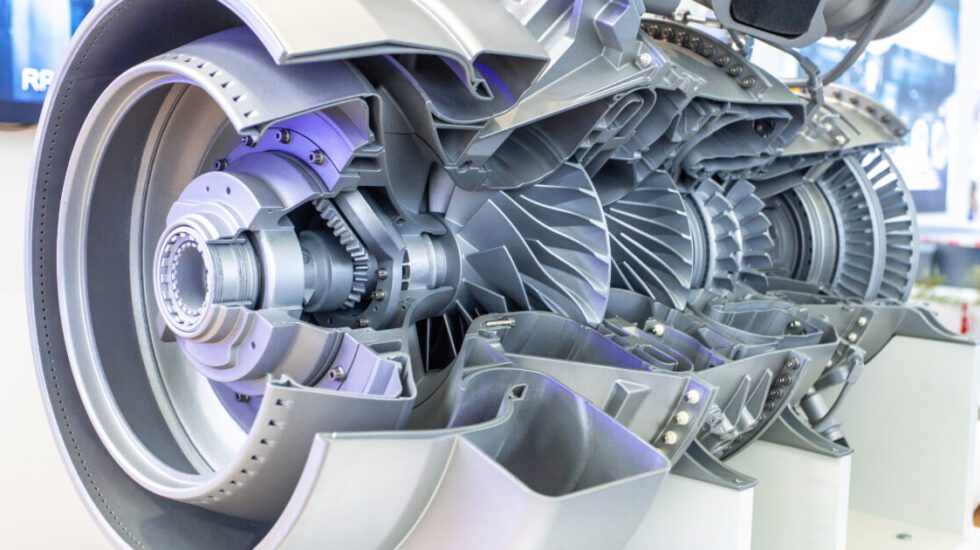

Optimization of Blade Design

Technological Uncertainty: Designing the most efficient blade shape involves challenges in determining the ideal angle, curvature, or surface texture to maximize airflow and minimize energy consumption.

SR&ED Activity: Engage in iterative testing and prototyping to refine blade designs. Use simulations and measurements to improve aerodynamic efficiency.

Noise Reduction Technology

Technological Uncertainty: Reducing noise from industrial fans without compromising performance is challenging. The effectiveness of different noise reduction technologies is often uncertain.

SR&ED Activity: Research and experiment with innovative noise reduction materials and designs. Evaluate their impact on fan performance to find optimal solutions.

Energy-Efficient Motor Integration: Custom Fan Manufacturing

Technological Uncertainty: Integrating energy-efficient motors into fan systems presents uncertainties related to compatibility, control mechanisms, and overall system optimization.

SR&ED Activity: Develop and test control algorithms, experiment with various motor types, and conduct trials to achieve the most energy-efficient motor integration for your applications.

Advanced Sensor Integration for Condition Monitoring

Technological Uncertainty: Implementing advanced sensors for real-time monitoring and predictive maintenance involves challenges in sensor selection, integration, and data analytics.

SR&ED Activity: Research sensor technologies, develop algorithms for predictive maintenance, and integrate sophisticated monitoring systems into fan units.

Maximize Your SR&ED Claims

To benefit from the SR&ED program, it’s crucial to meticulously document your R&D activities, including the technological uncertainties faced and the systematic investigation conducted. Each SR&ED claim is unique, and specific eligibility requirements must be met.

Ready to explore SR&ED tax credits for your custom fan manufacturing?

Contact Ayming Canada today for expert guidance on qualifying activities and maximizing your claims. Don’t miss out on valuable funding opportunities—let us help you navigate the complexities of the SR&ED program.

Contact us today!

One of our experts will be in touch shortly.

No Comments