Maximizing SR&ED Benefits for EV Battery Gigafactory Innovations

The rise of electric vehicles (EVs) has sparked a global race to establish EV battery gigafactories, vital for the production of high-performance batteries. However, developing and scaling these advanced manufacturing facilities is no small feat. Companies face significant technological uncertainties, making them ideal candidates for Canada’s Scientific Research and Experimental Development (SR&ED) tax credits. Let’s explore the challenges and opportunities for innovation in setting up an EV battery gigafactory.

-

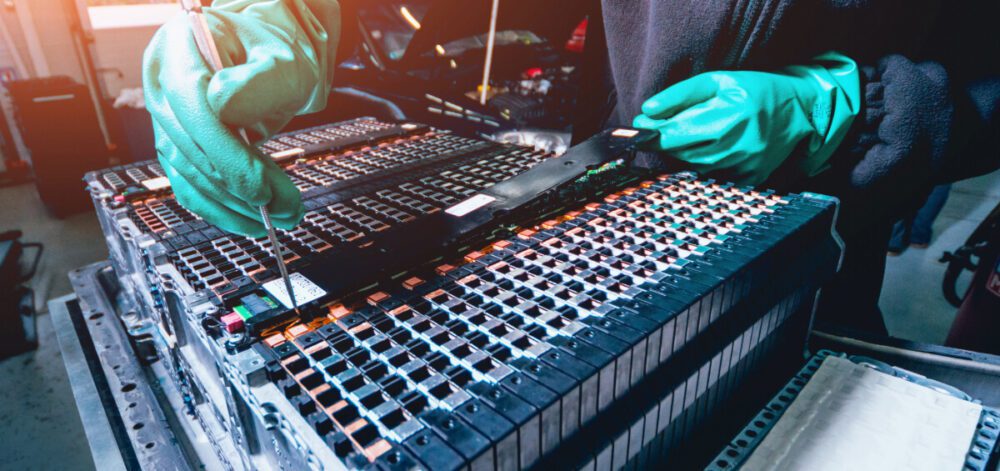

Material Innovation and Performance

Technological Uncertainty: Scaling up novel battery chemistries while maintaining performance.

Example: Transitioning from laboratory-tested materials, such as silicon anodes or solid-state electrolytes, to mass production often results in unpredictable behaviors. Extensive testing and process refinement are required to optimize material properties like energy density and safety.

-

Manufacturing Process Optimization

Technological Uncertainty: Maintaining quality and efficiency in large-scale production.

Example: Uniformly coating electrode materials in high-speed roll-to-roll manufacturing can be challenging. Experimentation with parameters like speed, pressure, and temperature is essential to ensure consistent quality across all battery cells.

-

Battery Cell Design and Integration

Technological Uncertainty: Creating flexible designs for different EV models.

Example: Designing cell formats that balance energy density and thermal management requires iterative development and validation, especially to address overheating concerns in diverse vehicle architectures.

-

Thermal Management Systems

Technological Uncertainty: Preventing battery overheating during operation.

Example: Experimenting with advanced cooling solutions, such as liquid cooling systems or phase-change materials, to ensure performance and safety under various environmental conditions.

-

Automation and Robotics

Technological Uncertainty: Customizing robotics for delicate battery components.

Example: Developing robotic systems to handle diverse shapes and sizes of components without causing damage involves innovative engineering and testing to achieve reliability.

-

Quality Control and Testing

Technological Uncertainty: Ensuring defect-free battery cells.

Example: Creating non-destructive testing methods to detect flaws in battery cells before deployment requires overcoming challenges in precision and accuracy, especially as battery designs become more complex.

-

Environmental and Safety Regulations

Technological Uncertainty: Meeting stringent compliance requirements without impacting efficiency.

Example: Developing innovative recycling methods for hazardous materials like solvents or heavy metals used in production to align with environmental standards.

-

Supply Chain Integration

Technological Uncertainty: Sourcing raw materials reliably and sustainably.

Example: Developing strategies to secure critical materials like lithium and cobalt while balancing costs and ensuring ethical sourcing practices.

-

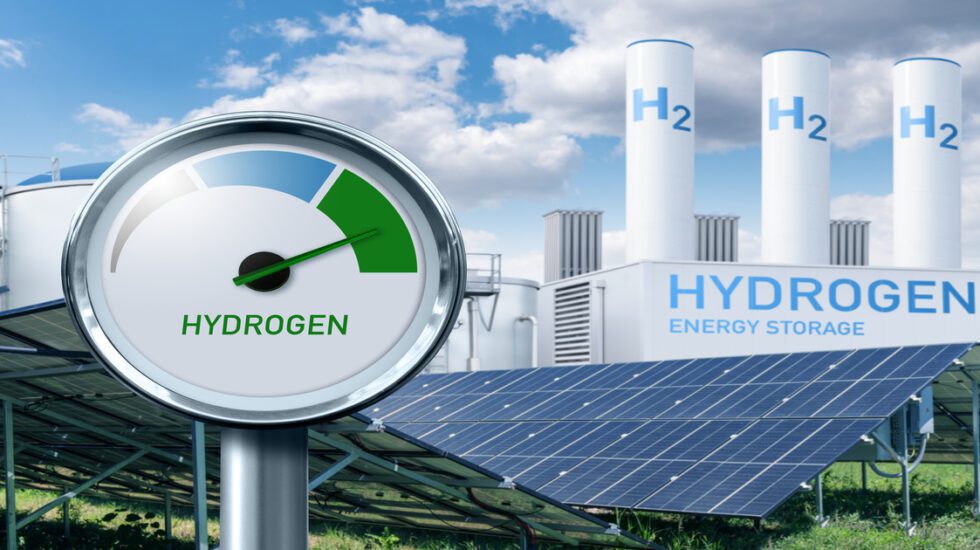

Energy Efficiency and Sustainability

Technological Uncertainty: Reducing the gigafactory’s carbon footprint.

Example: Experimenting with renewable energy integration, such as on-site solar or wind power, to achieve sustainable and cost-effective energy use during production.

-

Recycling and Reuse

Technological Uncertainty: Incorporating recycled materials into battery production.

Example: Creating efficient processes to extract and purify materials from end-of-life batteries requires innovative separation techniques and extensive validation to maintain quality.

Seizing SR&ED Opportunities with Ayming Canada

Addressing these uncertainties involves systematic experimentation and research, making EV battery gigafactories prime candidates for SR&ED tax credits. By documenting hypotheses, testing methods, results, and iterations, companies can unlock significant financial incentives to fuel innovation and accelerate the shift toward sustainable energy solutions.

For manufacturers venturing into EV battery production, SR&ED support not only offsets R&D costs but also empowers technological breakthroughs critical to staying competitive in this fast-evolving market. Contact Ayming Canada today to leverage our deep SR&ED expertise.

Contact us today!

One of our experts will be in touch shortly.

No Comments